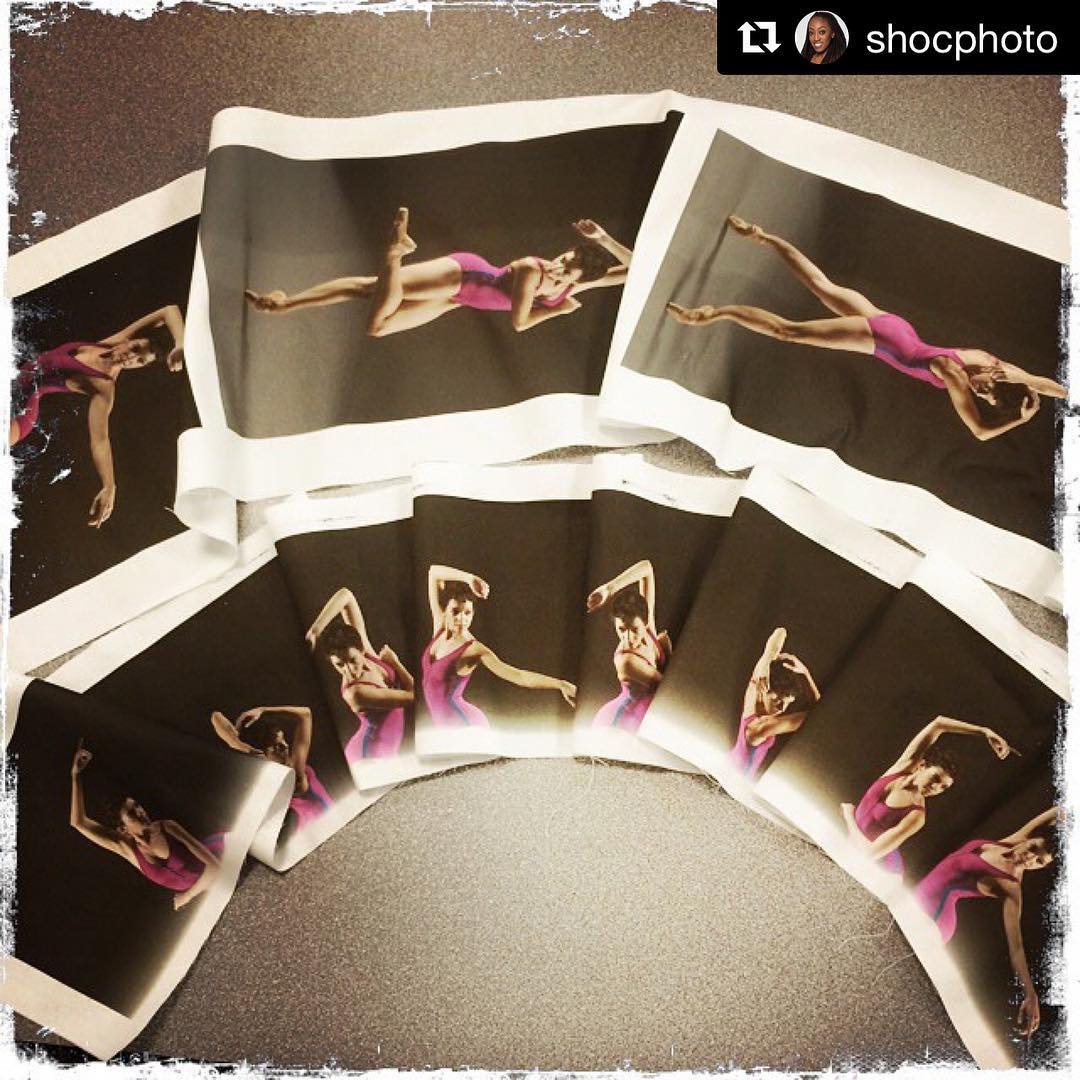

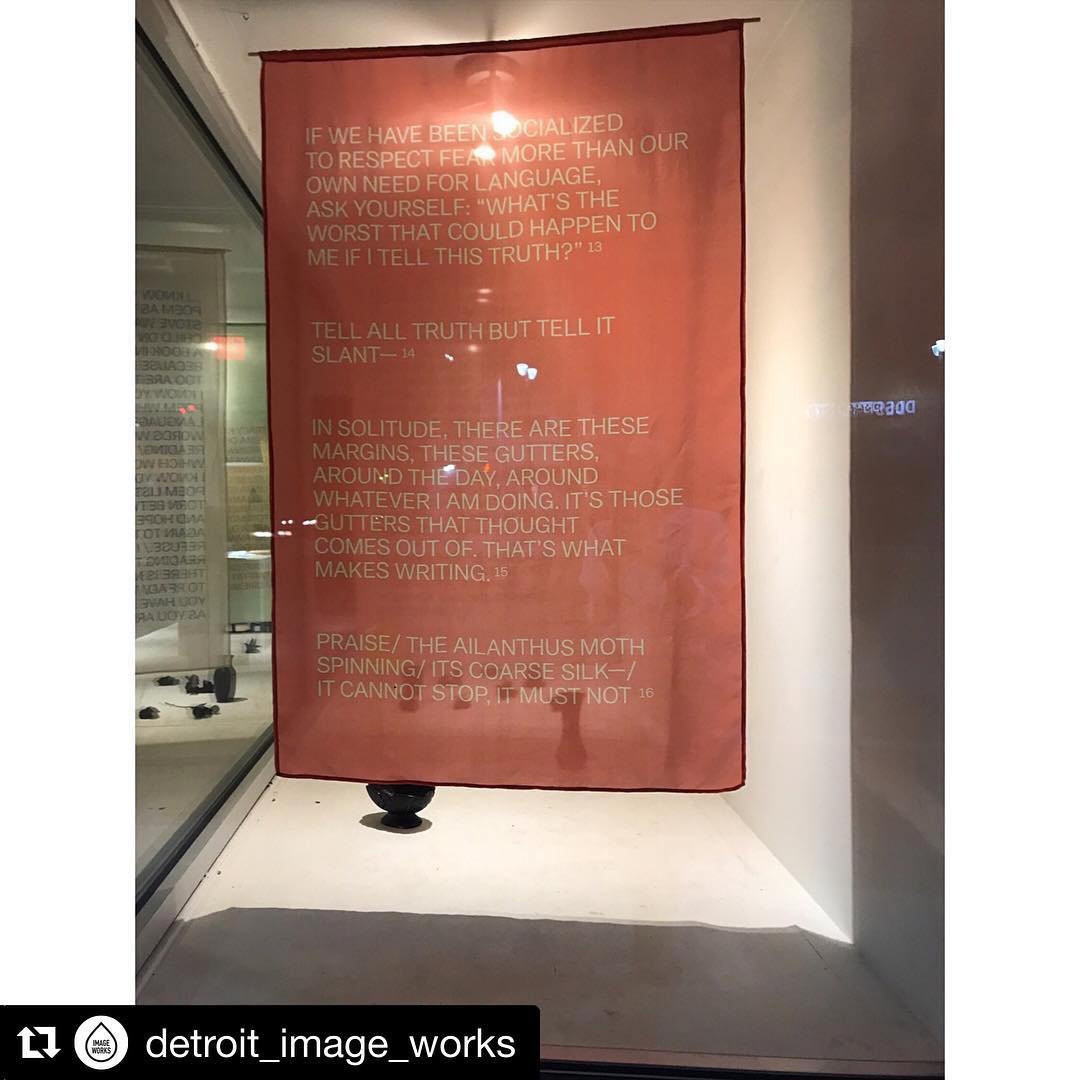

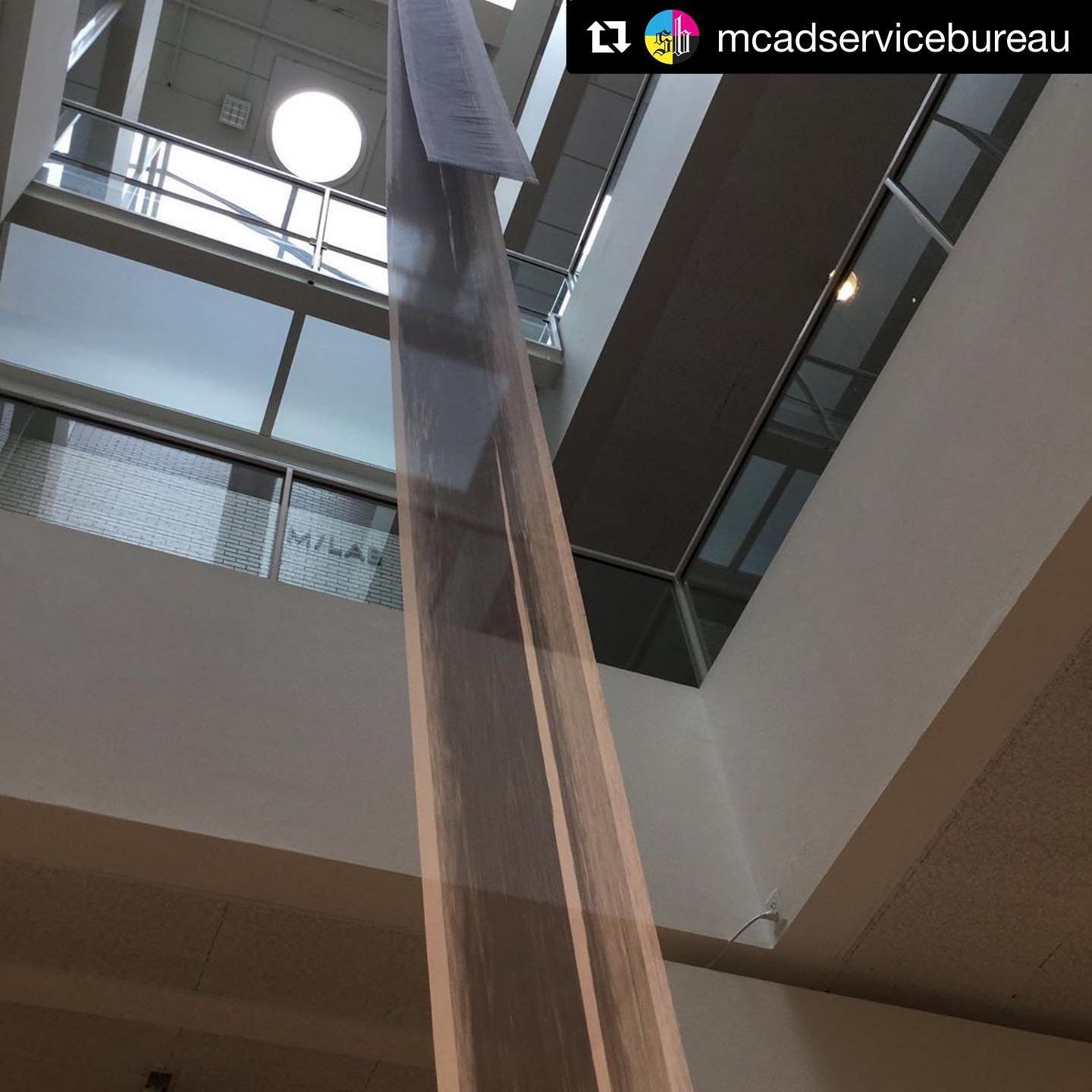

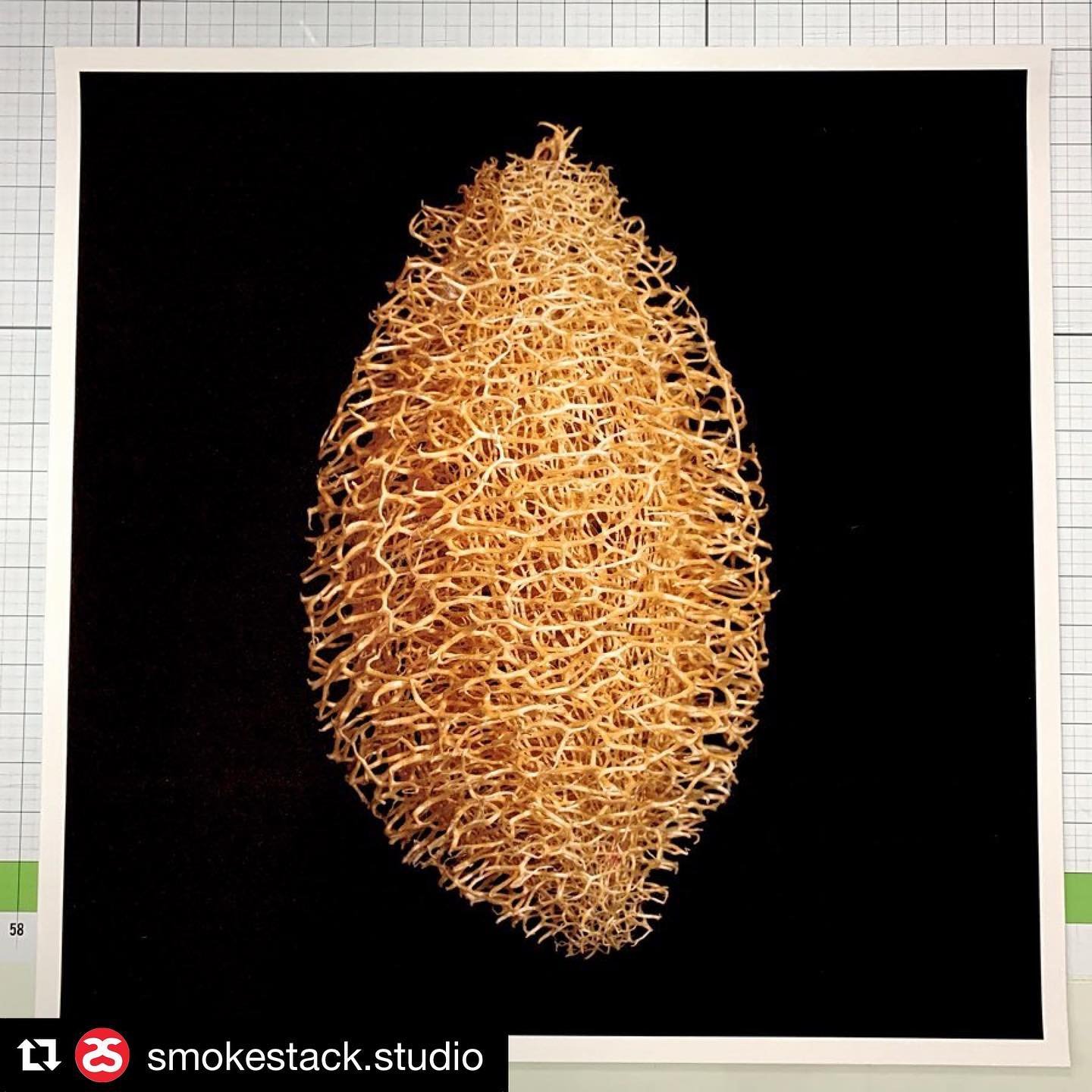

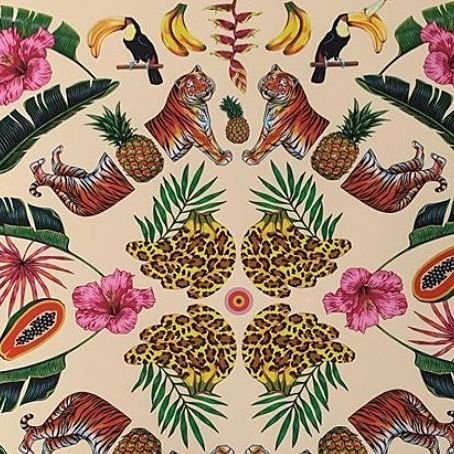

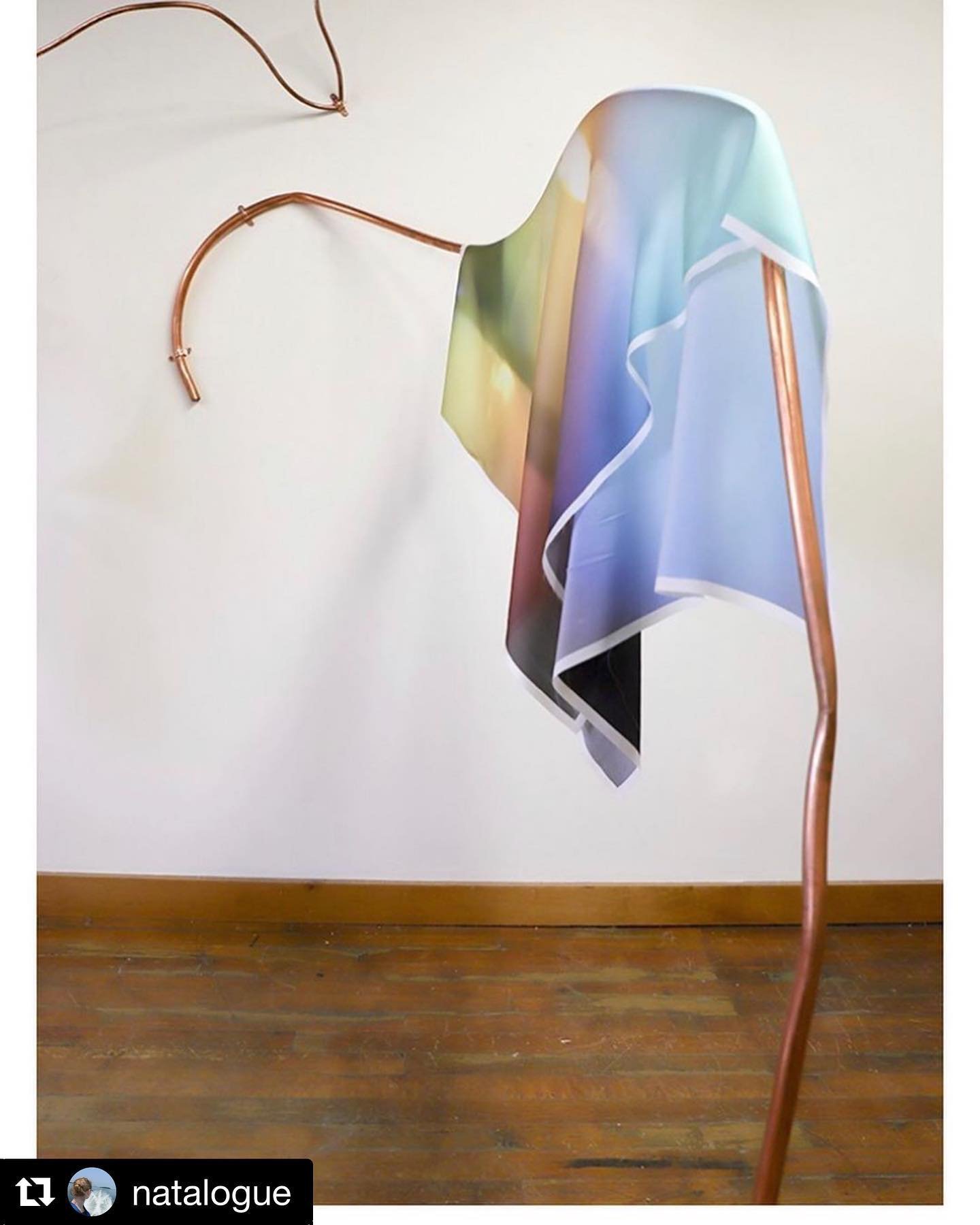

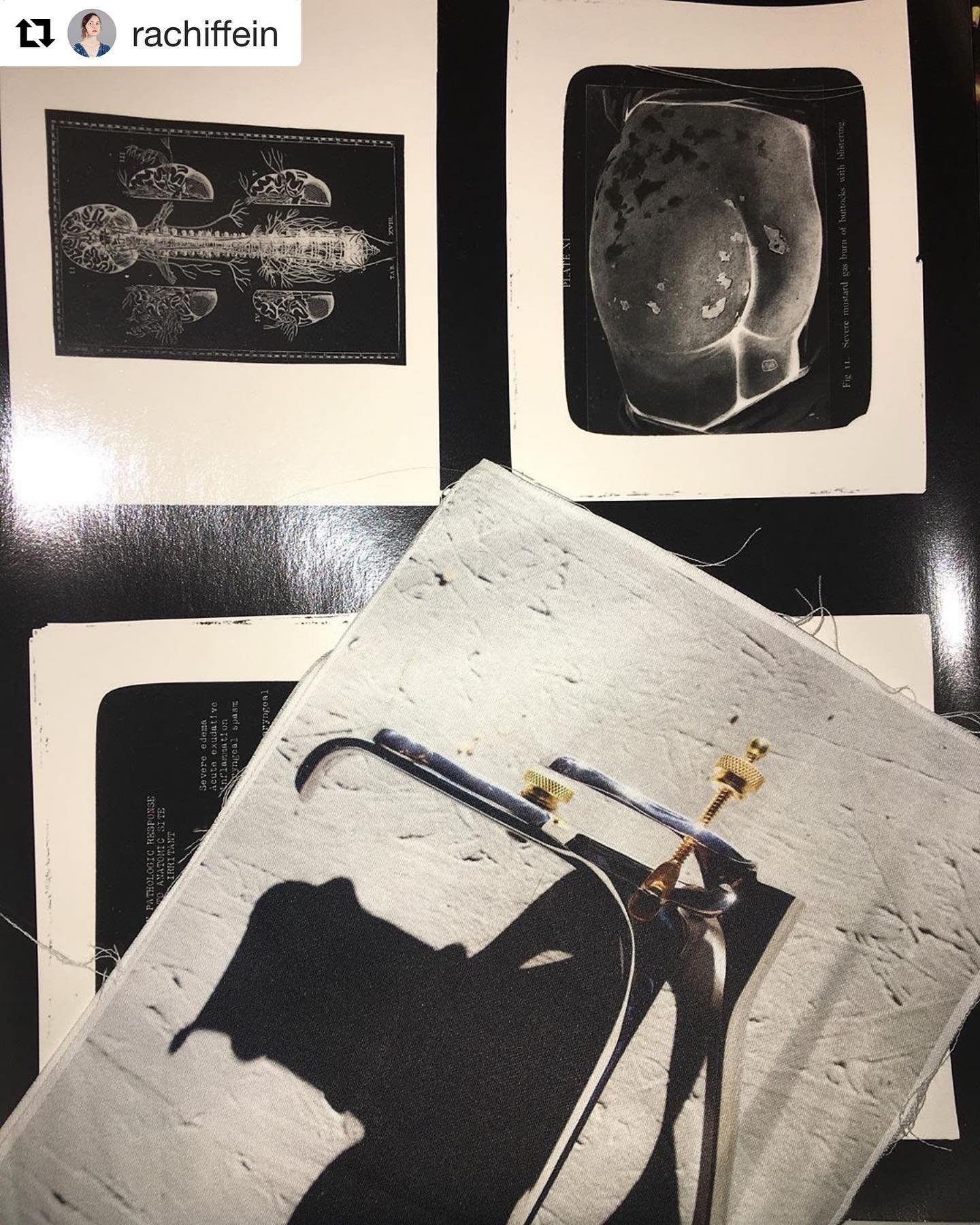

Inkjet-printable silks, cottons, linens, rayons, and nylons

We treat for Pigment, Acid, Reactive, and Disperse dye ink systems

Jacquard Inkjet Fabric systems has merged with our parent company, Jacquard Products, to provide streamlined fabric coating services to our valued customers.

Please contact service@jacquardproducts.com, or call 707-433-9577 to place orders and obtain our current list of available fabrics

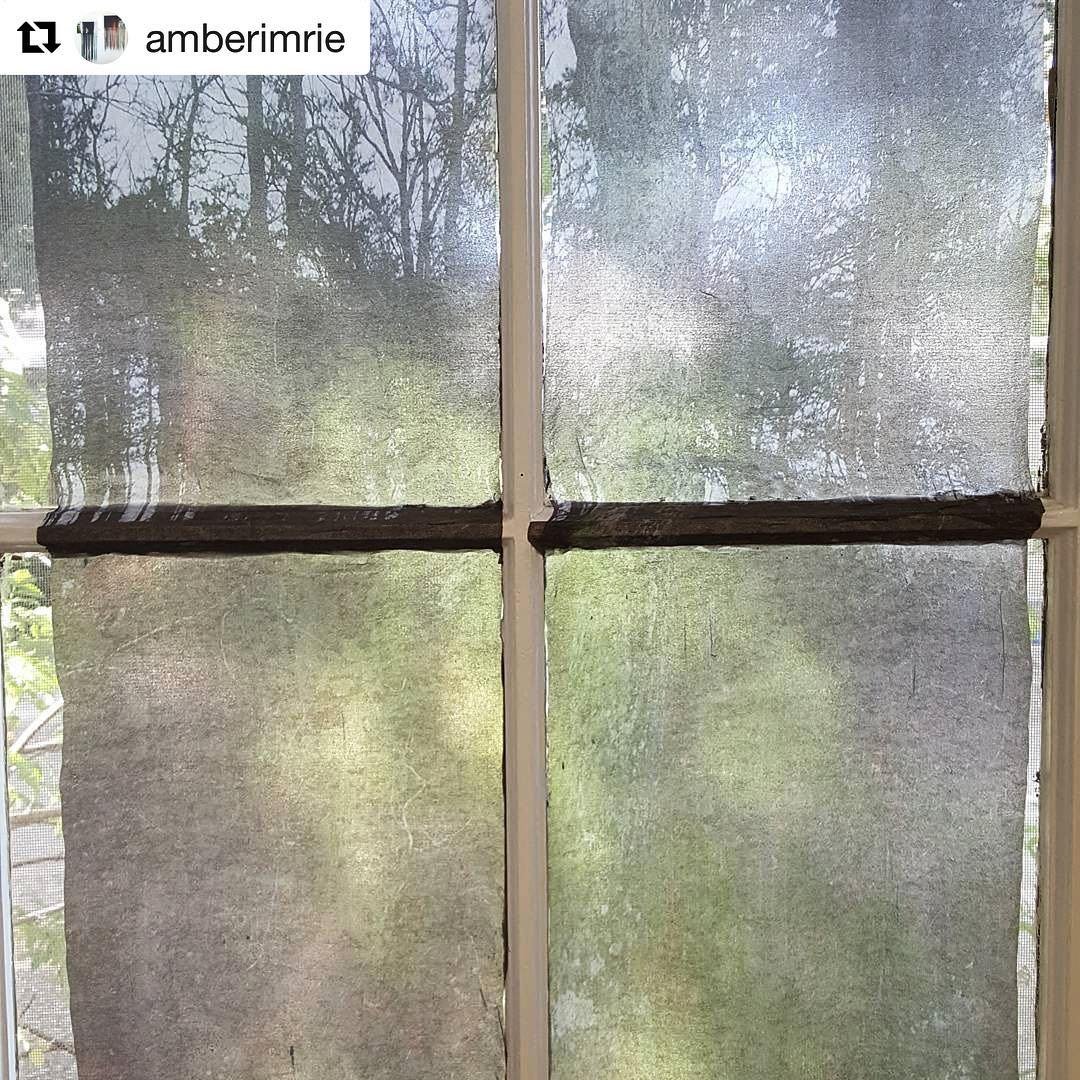

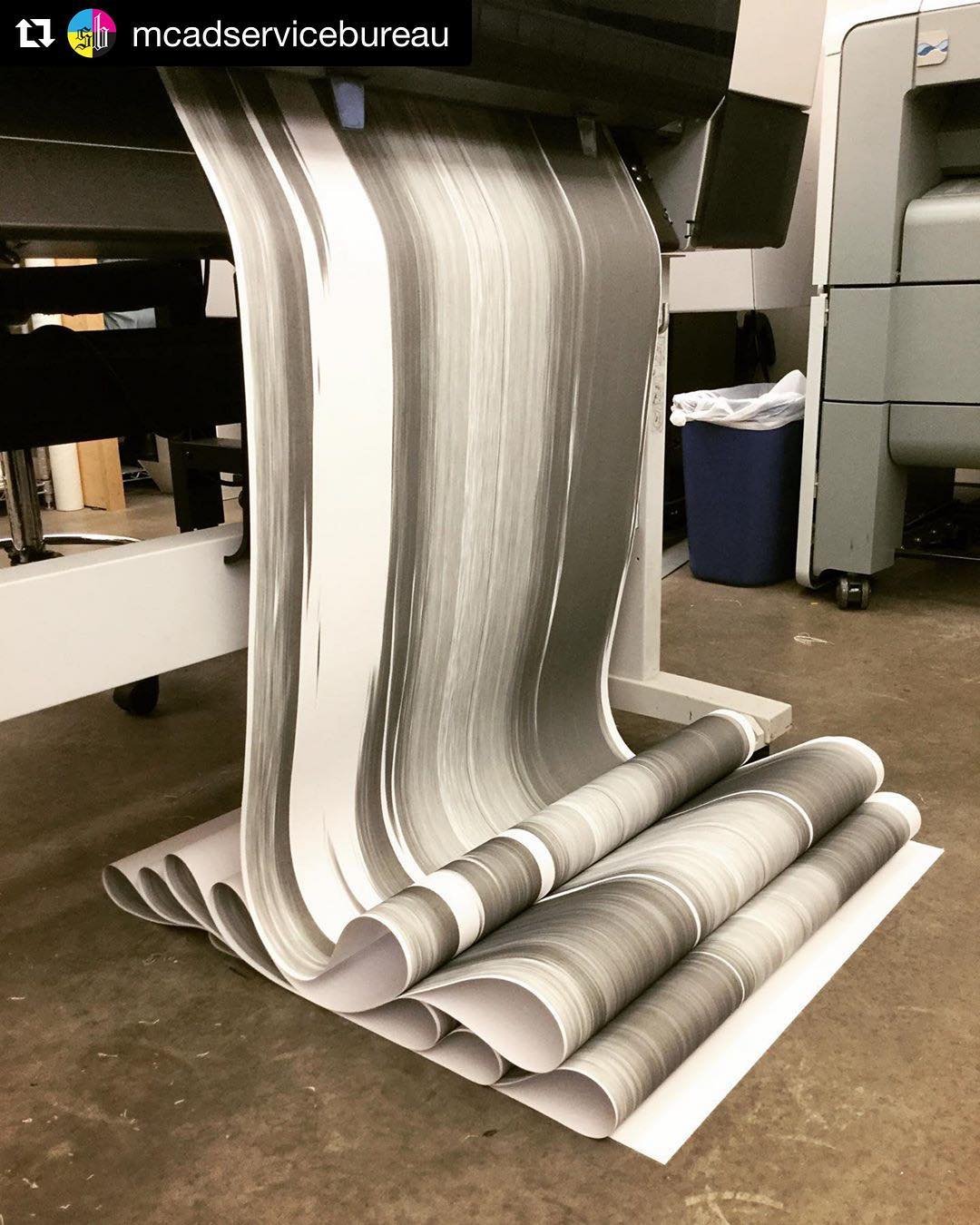

Jacquard Inkjet Fabric Systems offers custom treatment of textiles for direct inkjet printing, as well as off-the-shelf inkjet-printable fabrics. Send us your fabric and let us prepare it for inkjet printing! Jacquard was an early pioneer of inkjet textile technology, and we still offer the highest performing coatings for digital textile printing available, for both pigment and dye inks (Acid, Reactive, and Disperse). With low minimums and a wide range of options, Jacquard supplies ready-to-print textiles and treatment services, including various coating options, paper-backing, and trimming. Jacquard’s specialty is in coatings for dye inks and natural fabrics such as silks, linens, canvas and cottons. For pigments inks, we offer a unique coating that provides unparalleled color vibrancy and fastness. All production is done in California to the highest quality standards.

SERVICES:

Custom Fabric Coating

Paper Backing

FABRICS:

Cotton Sateen - 60”

Cotton Percale - 60”

Cotton Twill - 8.5 oz - 60”

Cotton Canvas - 6.5 oz - 56”

Linen - 5.5 oz - 56”

Linen - 7.5 oz - 56”

Silk Organza - 55”

Silk Habotai - 10 mm - 55”

Don’t see what you’re looking for? Have a special project in mind? Need to treat thousands of yards of fabric? We custom coat and paper back many fabrics and other substrates. We can coat up to 72” wide and paperback up to 60” wide.

| Prices per Linear Yard | Base Fabric Cost | 0-250 yds | 250-500 yds | 500-1000 yds |

|---|---|---|---|---|

| Paper Backing 59" | $3.30 | $3.30 | * | |

| Coating | $3.30 | $2.75 | * | |

| Cotton Sateen 60" | $6.90 | $6.90 | $6.10 | * |

| Cotton Percale 60" | $4.80 | $4.80 | $4.30 | * |

| Cotton Twill 8.5 oz 60" | $6.90 | $6.90 | $6.10 | * |

| Cotton Canvas 56" | $8.35 | $8.35 | $7.95 | * |

| Linen 5.5 oz 56" | $14.99 | $14.99 | $14.32 | * |

| Linen 7.5 oz 56" | $16.15 | $16.15 | $15.32 | * |

| Silk Organza 55" | $10.19 | $10.29 | $10.05 | * |

| Silk Habotai 10mm 55" | $13.59 | $13.69 | $13.29 | * |

| *Inquire for bulk rates | ||||

** There is a 20 yard minimum for all fabric purchased or droppshipped to Jacquard for coating and/or paper-backing. This does not apply to raw fabric purchases that will not be treated.

*** There is a minimum order dollar value for $200. Orders with a lesser value will be accepted, but rounded up to $200.

****If fabric for a single order arrives in pieces and any piece is less than 17 yards of continous fabric, each must be sewn together before coating (see cost for sewing below).

Additional Services & Fees

Pre-rolling: $25 per roll / $45 for multiple pieces

Sewing: $12 per seam

Packing: $4 per roll

Trimming (Slitting): $8

WHAT KIND OF COATING DO I NEED?

There are 3 main types of digital printing that we serve: Pigment printing, reactive dye printing, and acid dye printing.

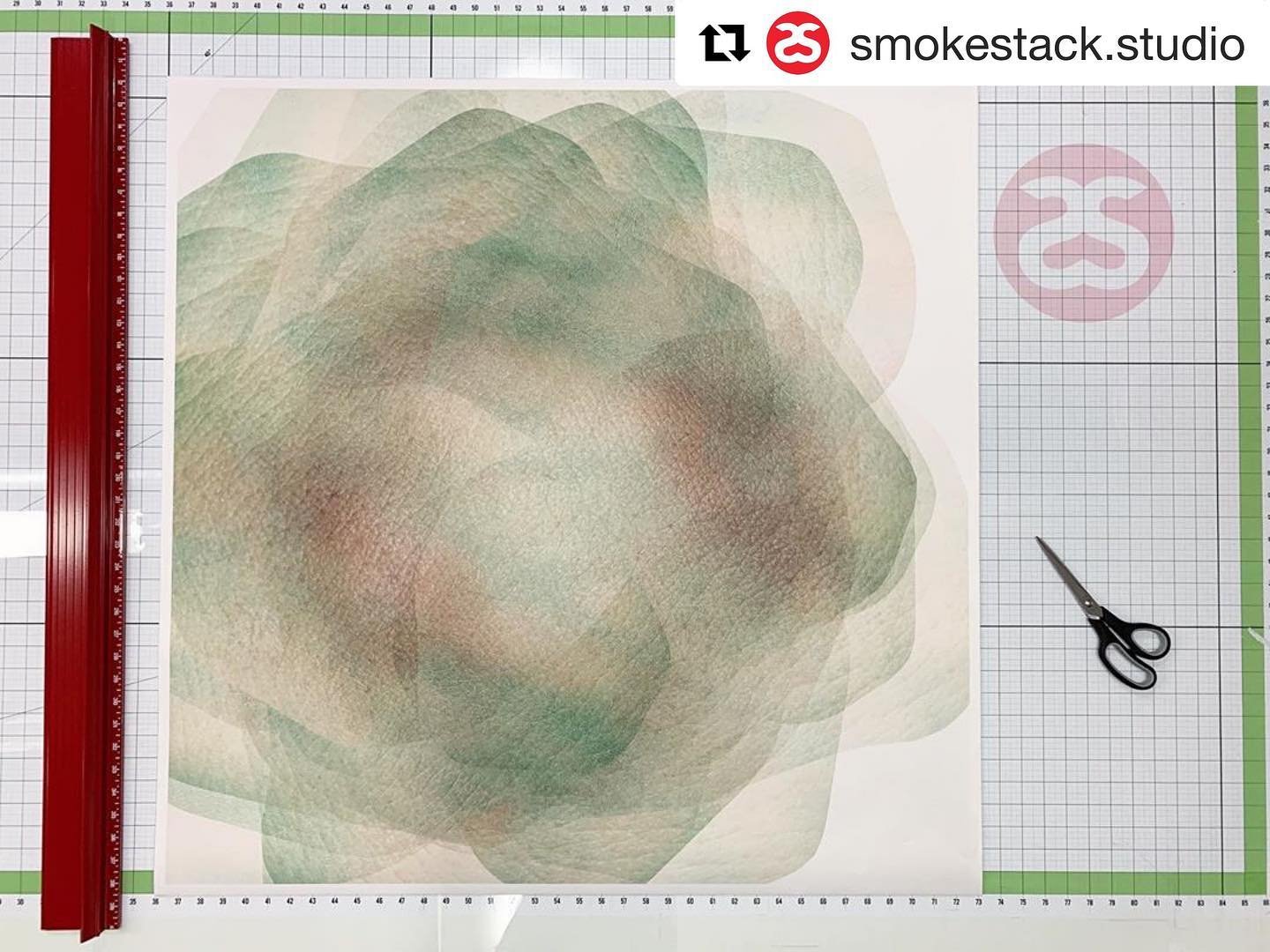

Pigment prints work on all fabrics except polyesters and is the most popular type of printing at this time. Pigment inks are basically like paints—there is a colorant, a carrier, and a binder. Standard desktop printers and wide format plotters (Epson, Canon, HP) have weak binders that are suitable and designed for paper. Textile-Specific pigment inks have a much stronger binder. We treat fabrics with our proprietary coating called Fabrisign. There are other pigment coatings available for purchase, but ours works differently than the rest. It is much more viscous and seems to act much more strongly, attracting the pigment chromophores themselves rather than enhancing binders or utilizing other ways of making a better pigment print. It also acts as an anti-migrant, preventing the printer ink from bleeding. Our pretreatment will react with standard graphics inks (the Epson, Canon, and HP inks) and actually make them highly water resistant. Textile-specific pigment inks become washfast ( by commercial standards—there is still commercially acceptable fading that occurs with all pigment prints, digital or otherwise. In order to be considered “washfast” an item needs to withstand 5 washes under standard conditions—established water temp, wash vigor, etc.). Pigment inks generally stick to the surface—that’s by design. If they penetrated the textile, they would look less bright. Because of this, there is very little “print-through”, which means that you won’t see your print on the reverse side of the fabric. Pigments are considered highly lightfast, but are weak in crock (rubbing resistance) and washfastness

Reactive Prints work on Cotton, Linen, Rayon, other cellulosic fiber, as well as silk. Reactive inks are made with reactive dyes solubilized in a special carrier. The carrier is more or less specific to the print head (not to be confused with the printer!). All reactive prints need to be steam-set and washed after printing before use/sale. The essential principle of reactive coating is to alkalize the fabric, provide antimigration for the inks, and add a humectant to facilitate optimal steaming. Additionally, we add a special fixative to our coating which works lock the dyes to the fibers and keep the color from washing out in the first washes. Reactive (and acid) dye printing has more print-through than pigments and generally yield brighter, stronger colors. There are tricks to increase print-through, such as diluting the ink and increasing the printer’s output. Reactive dye printing is considered highly washfast and crockfast (resists rubbing) since the chromophores are creating a covalent bond with the fibers, but this bond is relatively easily broken by UV light, making reactive dyes not very lightfast.

Acid Prints work on silk, wool, nylon, acetate, and other protein fibers. Acid inks are made with acid dyes solubilized in a special carrier. The carrier is more or less specific to the print head (not to be confused with the printer!). The process is similar to reactive prints, except an ionic bond is formed rather than a covalent. The coating acidifies the fabric rather than making it more basic, and we do not add the additional fixative to our acid coating. Reactive dyes also seem to work well on silk coated for Acid. Nylon is one of the most temperamental of fabrics to print on, but it does work with acid coating and acid dyes.

Polyester is generally printed by printing on special transfer paper (in mirror image) then heat-pressing that paper to polyester. This is called “Dye-Sublimation” printing. We do not service folks who use polyesters, since they generally don’t need us. We have developed a pretreatment for printing direct onto polyester, but we provide that for large scale projects

Have a questions? Contact us by emailing service@jacquardproducts.com or call 707-433-9577.